GEMA Industrial

- compact complete control

- battery backup with integrated management

- relieable due to intelligent monitoring of the system

- control of several magnet plates in groups

bauma 2019

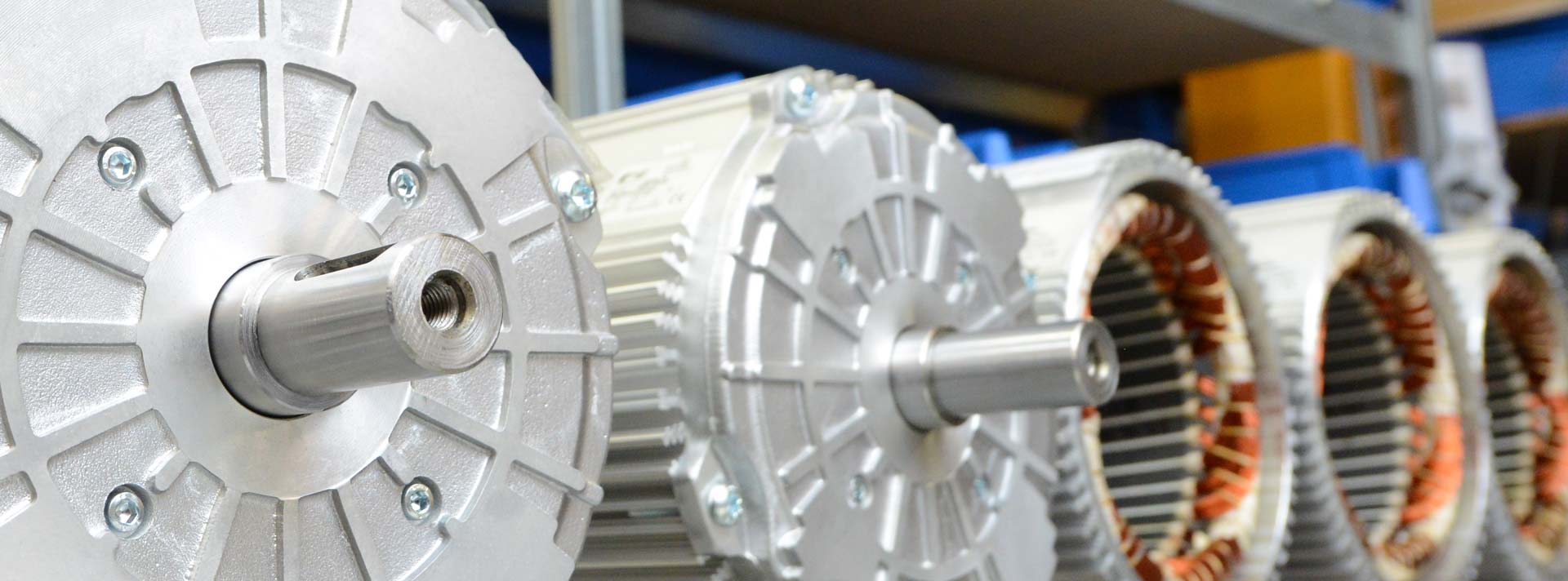

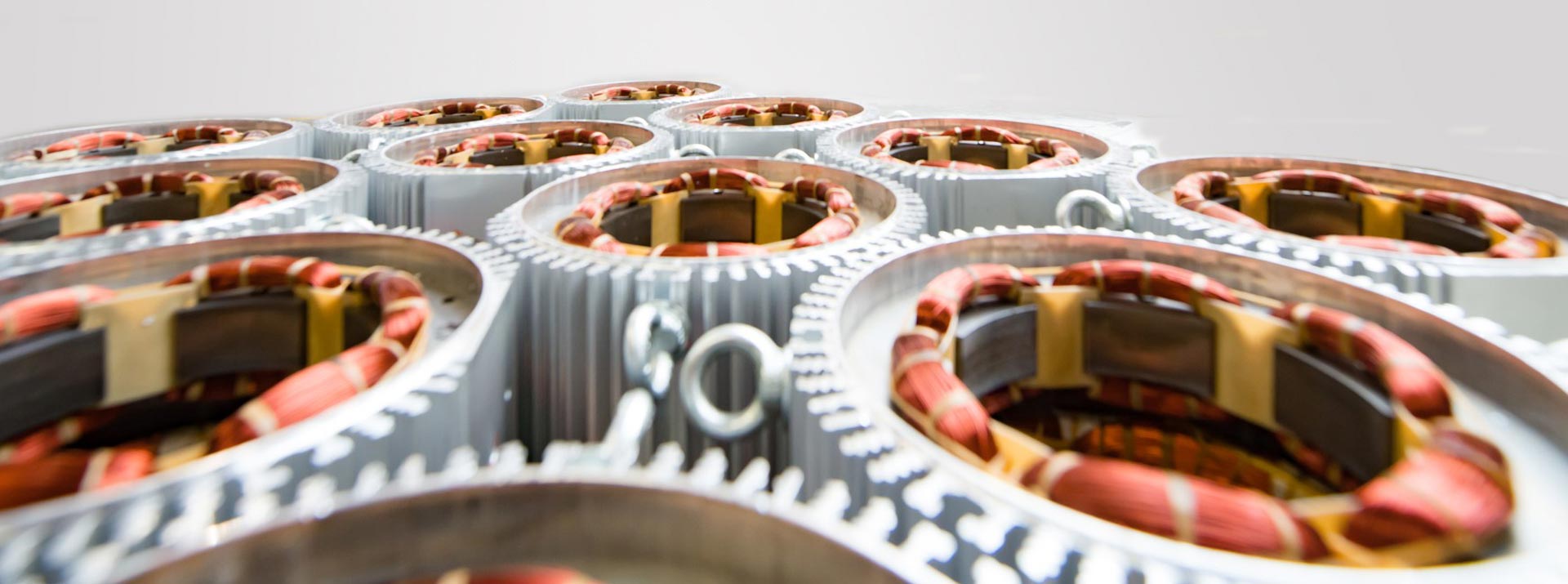

KW generators from Schwäbisch Gmünd rely on mobile power generation with an output of up to 550 kVA as an OEM. The brushless and variable-speed generators are used, for example, in mobile crushers.

On the picture (from left to right): Michael Werner (Sales Director), Marcel Werner (Strategic Purchasing), Tim Kurz (Systems Engineering) and Michael Kurz (Technical Director).

Published by SBM Verlag GmbH, bauMAGAZIN issue 05/2019

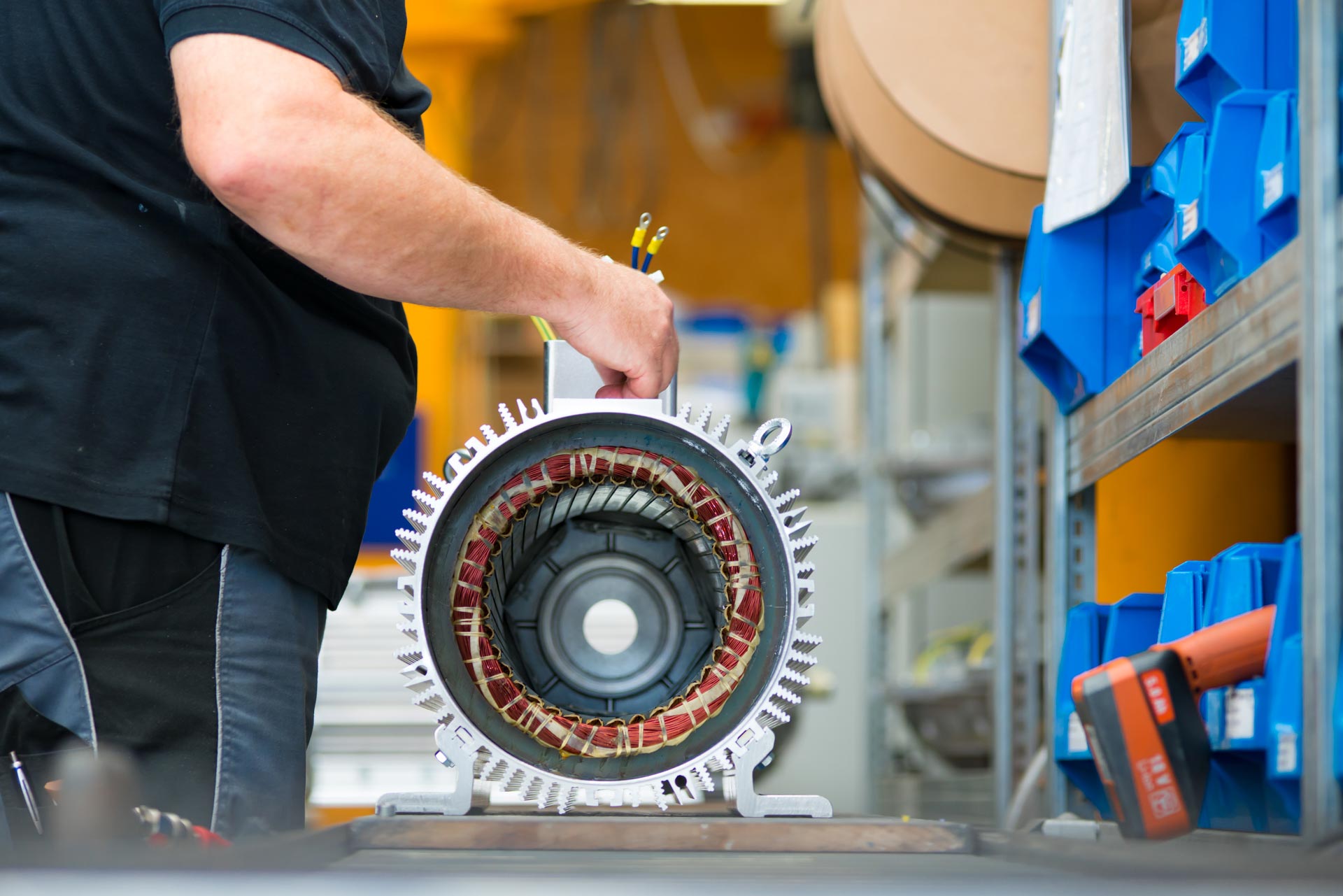

KW-Generator New development BG 355

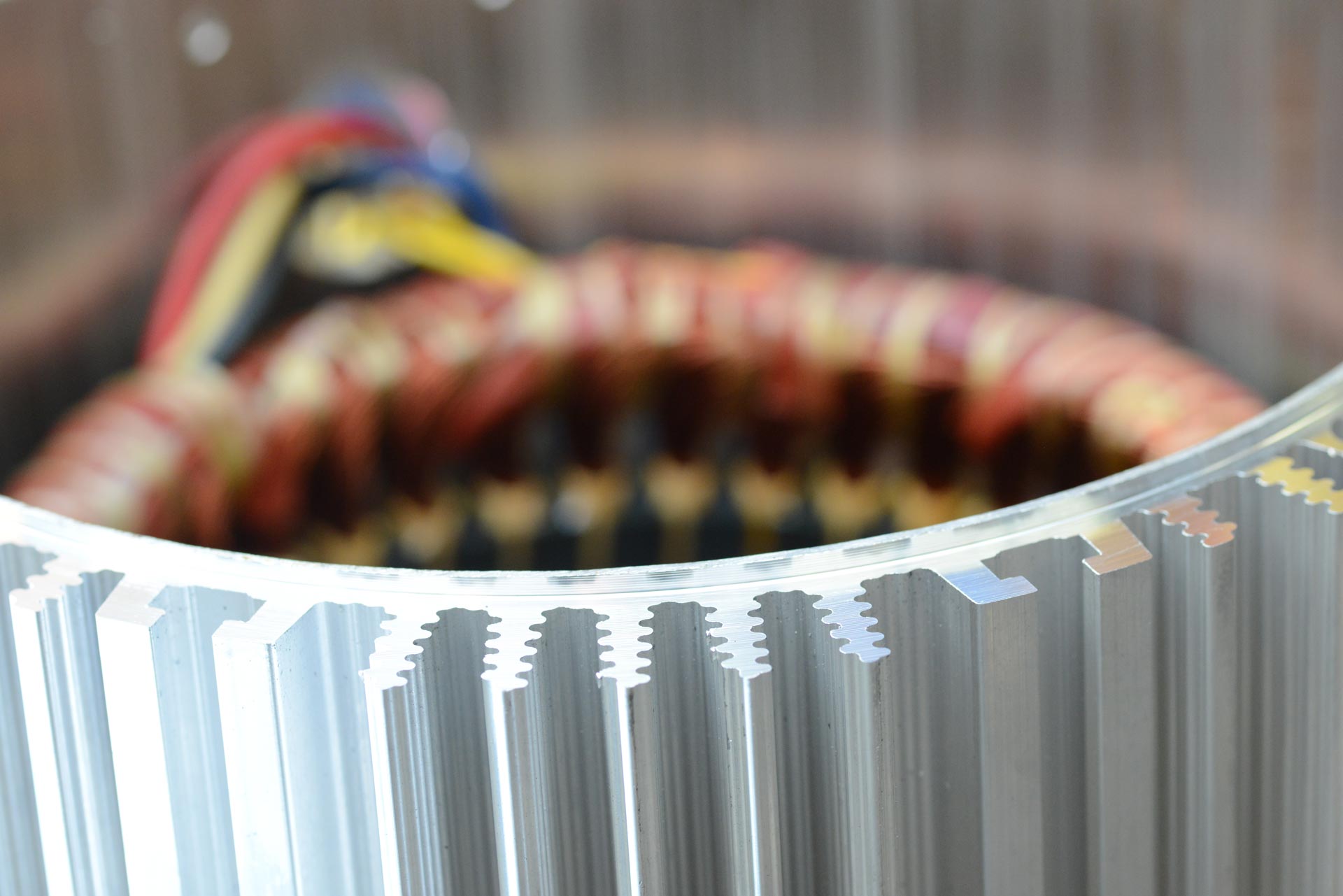

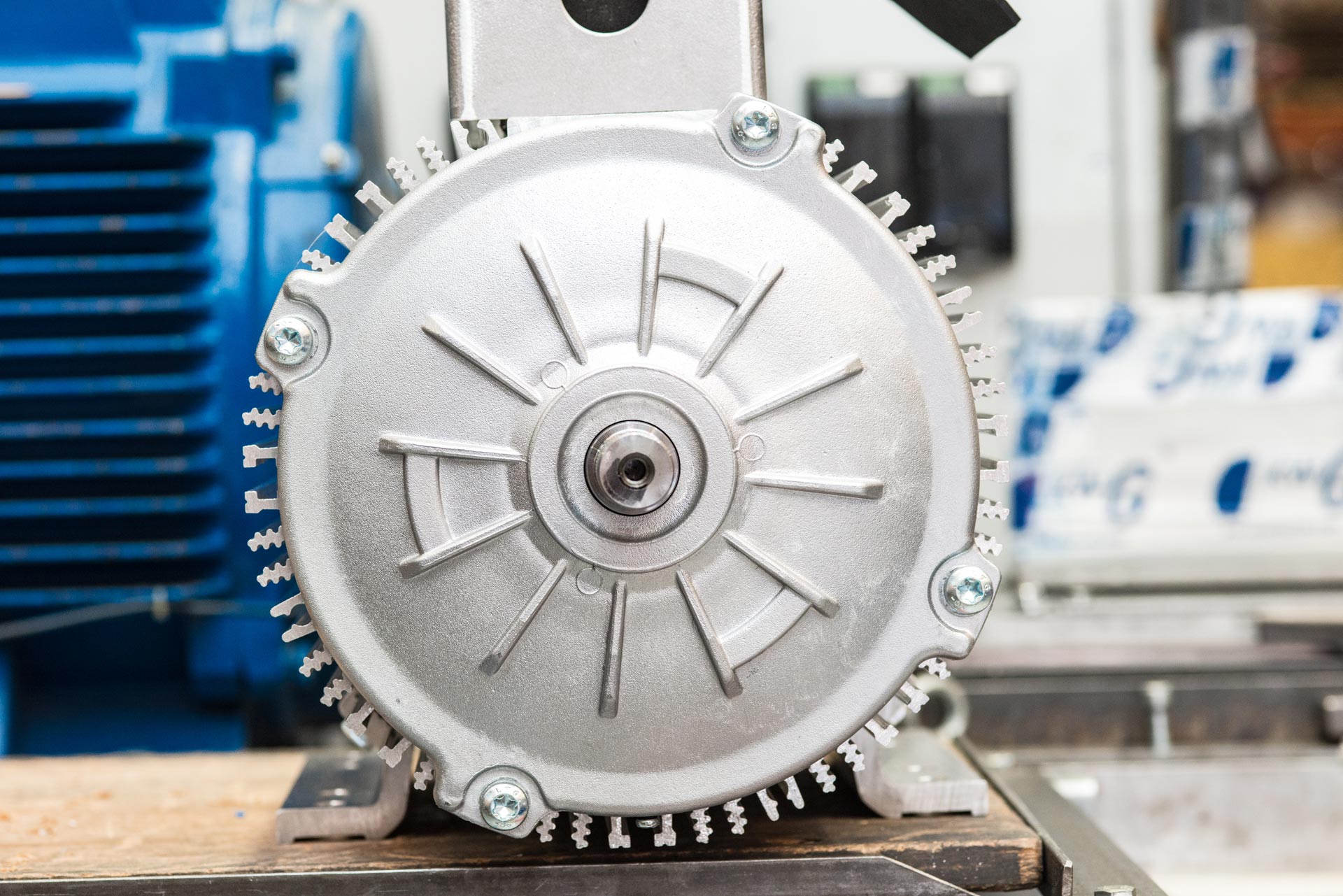

A new generator system is currently in development as the BG 355. The design will be similar to the familiar styling of all KW generators with an aluminium housing and bearing cover. Likewise with a protection class of IP 54 and higher.

Performance range 225 to 550 KVA.

Further information: Michael Kurz, Technology Director

Tel. +49 7171 10417-13

m.kurz@kw-generator.com

KW-Generator New development Service tool HMI

Development of the new HMI building block is now complete. The centrepiece is a powerful processor with universal interfaces such as USB, Profibus, CAN bus, network interface and universal I/O ports. The new HMI stands out on account of its simple, self-explanatory user interface with touch display, and it is ideal for a wide variety of applications: generator diagnosis, controller diagnosis, controlling inverters and the GEMA systems, long-term data capture via the optional SD card.

Further information: Michael Kurz, Technology Director

Tel. +49 7171 10417-13

m.kurz@kw-generator.com