Innovation

Innovative all-round solutions

We produce all-round, plug-in systems with control cabinet, touch control panel, insulation monitoring and mains analysis. A history and work profiles are supplied as standard or as individual units according to the customer’s wishes.

Developing solutions close to the customer – from the idea to series production

In a constant dialogue with the customer, we develop bespoke solutions such as special voltages and designs, CAN bus adaptations, programme and parameter modifications as well as further certifications.

TÜV certified

KW-Generator is certified to DIN ISO 9001:2015 and DIN ISO 14001:2015.

> Download certificate

History

KW-Generator: Power, Quality and Reliability Made in Germany

Since 2006, KW-Generator has been a symbol of excellence in the production of high-performance alternators.

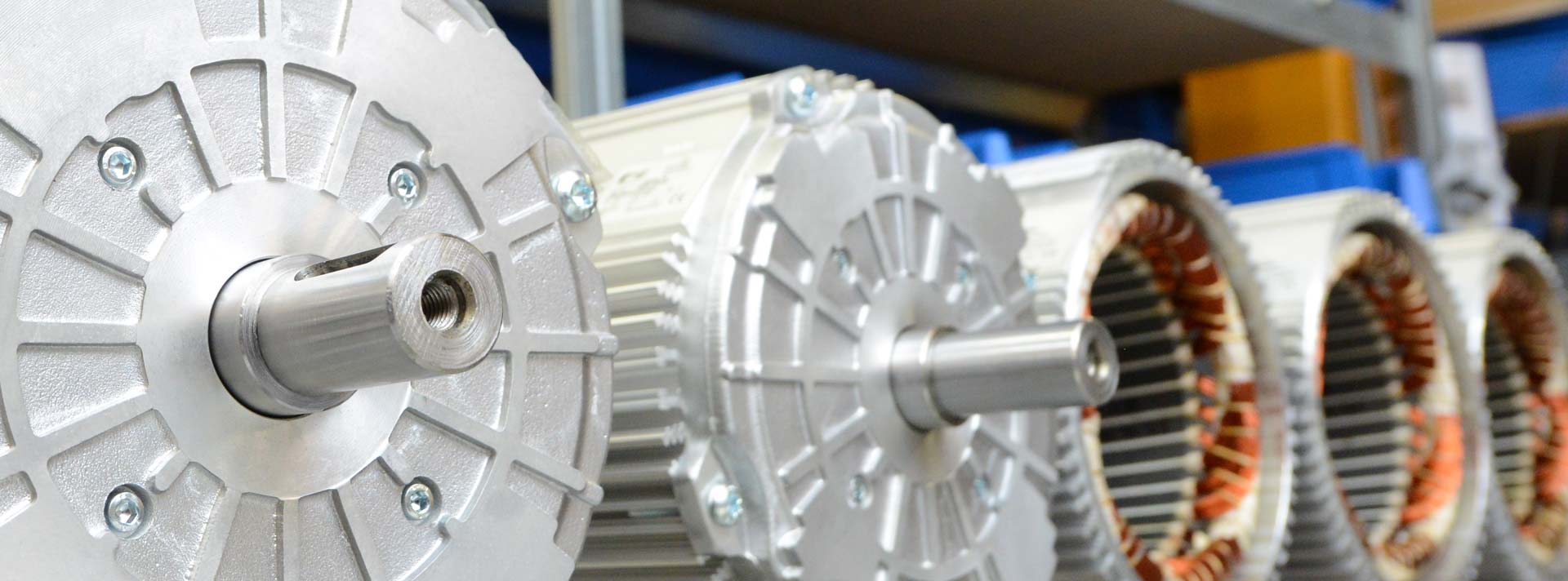

Based in Germany, we offer the most extensive range of alternators up to 550 kVA with a high protection class (from IP54 to IP67), designed to meet the demands of the industrial, construction, agricultural, transport and defense sectors.

German quality and engineering are at the core of our products, engineered for low maintenance, long service life, and consistent performance.

Our technical team combines advanced design and engineering skills with a flexible approach, capable of developing tailor-made solutions and integrating custom electronics for specific applications. We specialize in the design and production of customized alternators, built according to real customer needs, with comprehensive support starting from the design phase.

Since 2025, KW-Generator has become part of Linz Electric – Pedrollo Group, a strategic move that strengthens our international presence and allows us to offer an even broader range of integrated energy solutions.

Technology

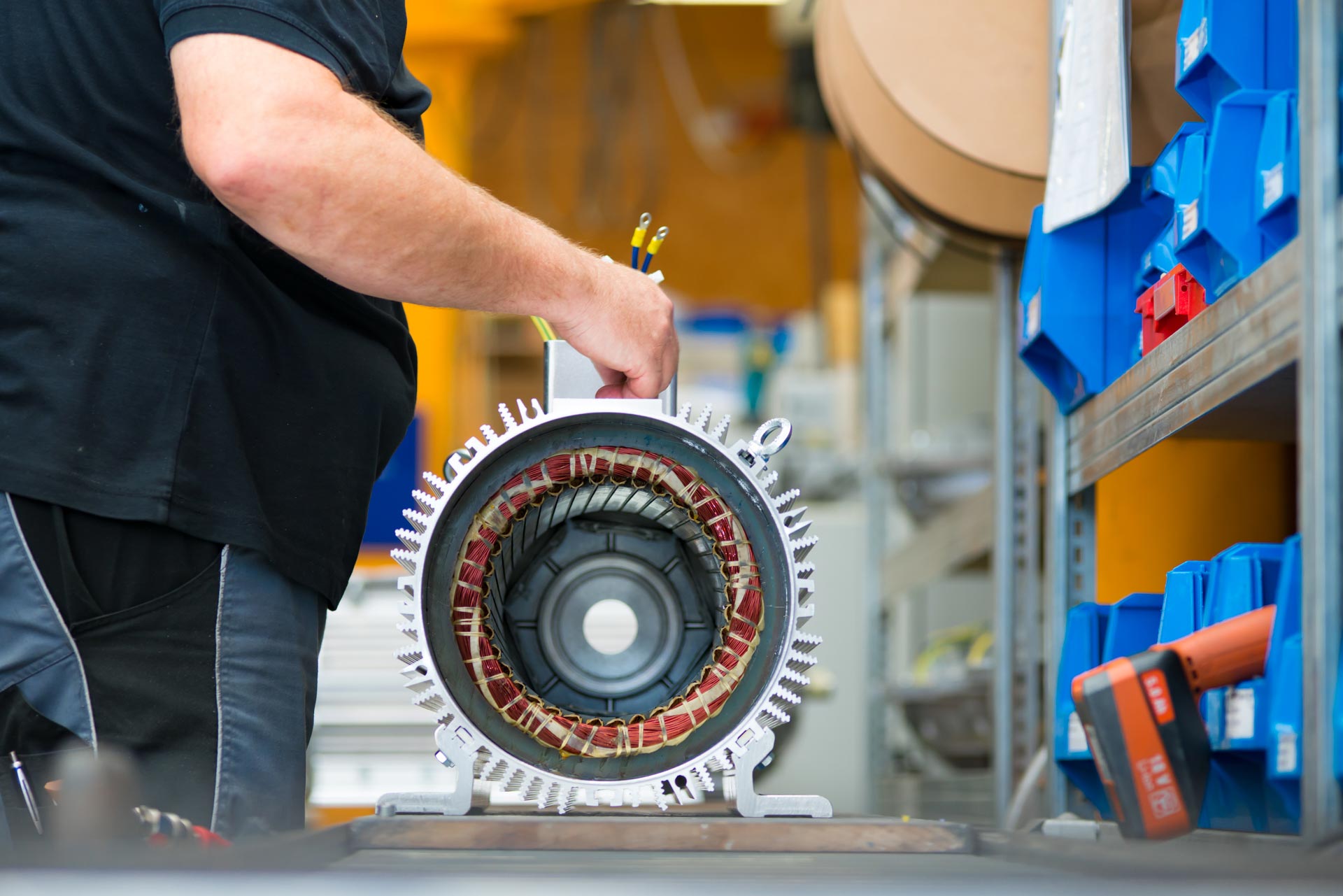

Brushless design

All KWG generators are brushless in design with a protection class of IP54 or higher. We guarantee maintenance-free operation up to 20,000 hours.

Vibration-proof, dust-proof, watertight

KW generators are suitable for the harshest conditions and perform well even in extreme environments.

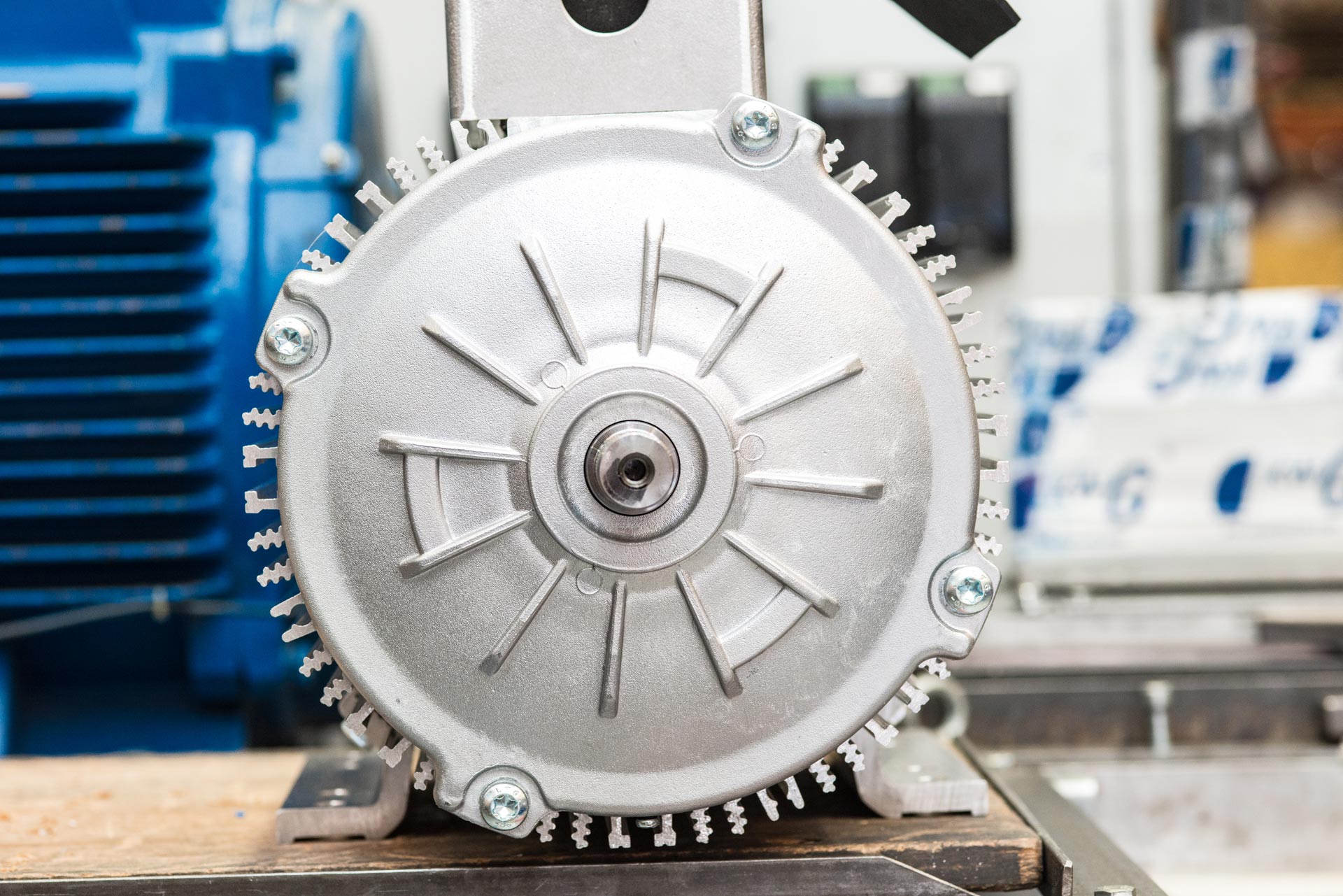

HPH Technology: KWG – High performance housing technology

There are fundamental housing innovations available in the generator sector. High-performance rib profiles combined with sophisticated geometries are taking generators to new levels with regard to power and noise emissions for the same installed size and dimensions as for previous types of IP54 generators.

DVR generator controller

The generator controller in DSP controller technology is equipped with CAN SAE1939 and True RMS measurement. Belt slip, drive motor overload and generator overload are things of the past with this controller. The system is tested to -40°C as standard and it meets the latest construction machine standard and is certified for use on railways.

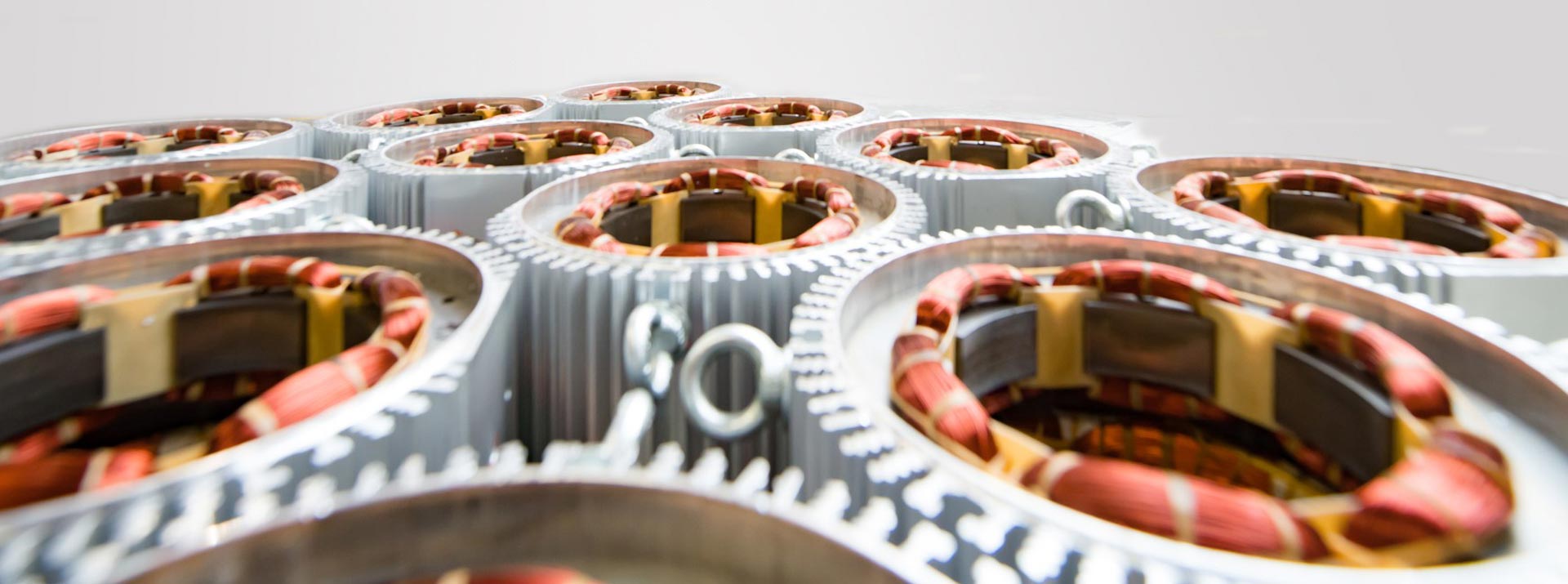

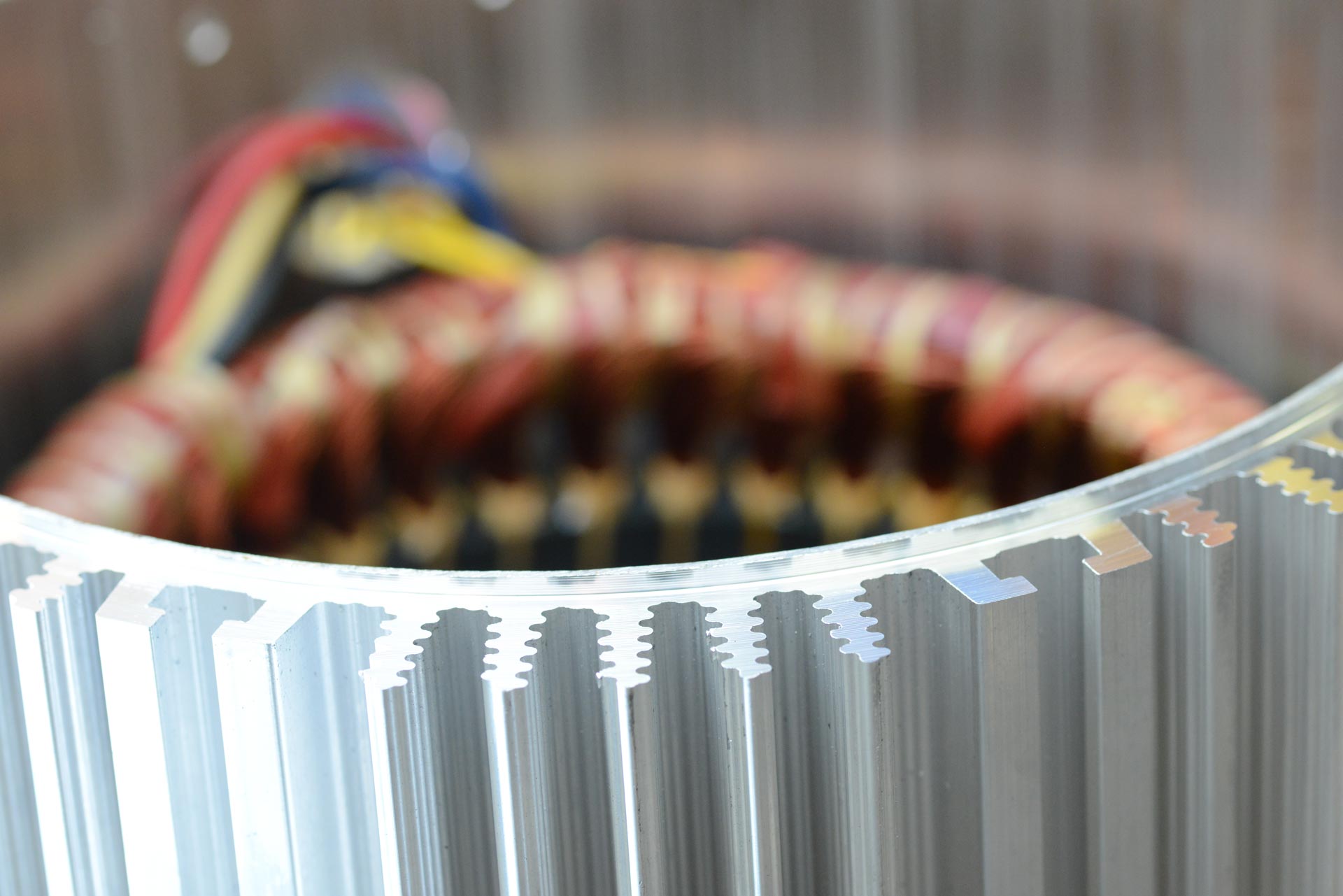

New sheet metal cutting geometry sets standard for the future

The use of HPH technology enables sheet metal geometries to be used which simply could not be achieved in the past. The power of the generator can be boosted by 20% by comparison with previous generators for the same length of iron. Powerful, performance-optimised 4-pole generators have been realised for the first time in the BG 132.

ITEM – Integrated Temperature Management

The averages of all winding temperatures are determined in the air flow inside the generator and provided to the controller together with many other parameters to calculate the maximum power in all operational situations for safe operation of the generator.